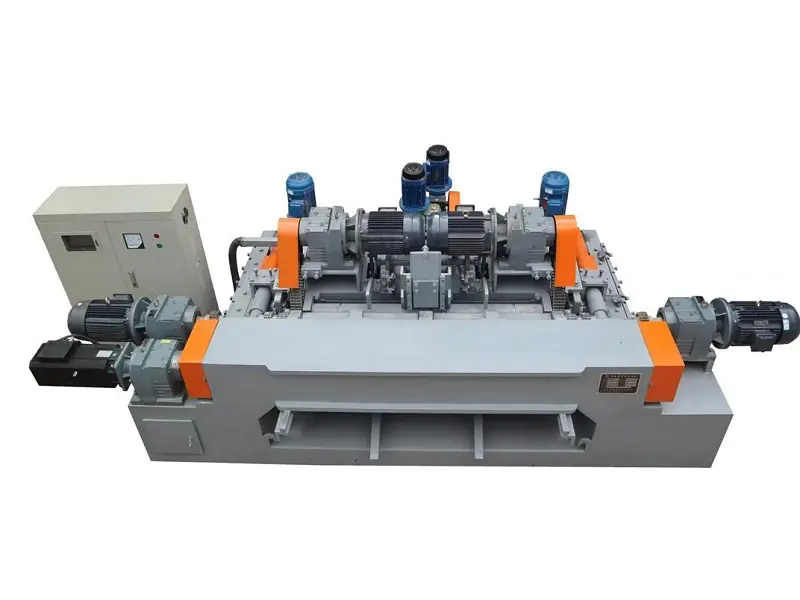

When investing in a wood veneer peeling machine, price is one of the key considerations.Understanding the factors that affect the price of these machines can help you make an informed decision and ensure that your investment is worthwhile. As a professional manufacturer of wood veneer peeling machines, TMC Machinery hopes this article will be helpful to you.

The wood veneer peeling machine price can range from as low as $8,000 to as high as $40,000, with significant price differences. The factors that affect the price include:

1. Model and Specifications:

Diameter and Hardness of the Logs: The larger the diameter and the harder the logs that the machine can peel, the higher the price will generally be. A machine capable of handling larger diameters or harder wood requires a more powerful motor, a more robust frame, and a larger bed to accommodate the different sizes of logs. For example, eucalyptus is harder than poplar, so the machine used to peel eucalyptus will require a more powerful drive roller motor and a stronger structure compared to one used for poplar, which raises the price.

Veneer Thickness Range: If the peeling machine can accurately peel thinner veneers and has a wider range of thickness, the price will increase accordingly. For example, a machine that can peel veneers ranging from 0.3 to 3 millimeters thick will be more expensive than one that can only peel veneers between 1 to 3 millimeters. This is because the former requires higher precision in the tools and control systems, thus increasing the cost.

Work Efficiency (Capacity): Machines with higher capacity typically cost more. This is because high-capacity machines usually have stronger motors, faster feed speeds, and more stable transmission systems. These high-performance components increase the overall cost of the machine.

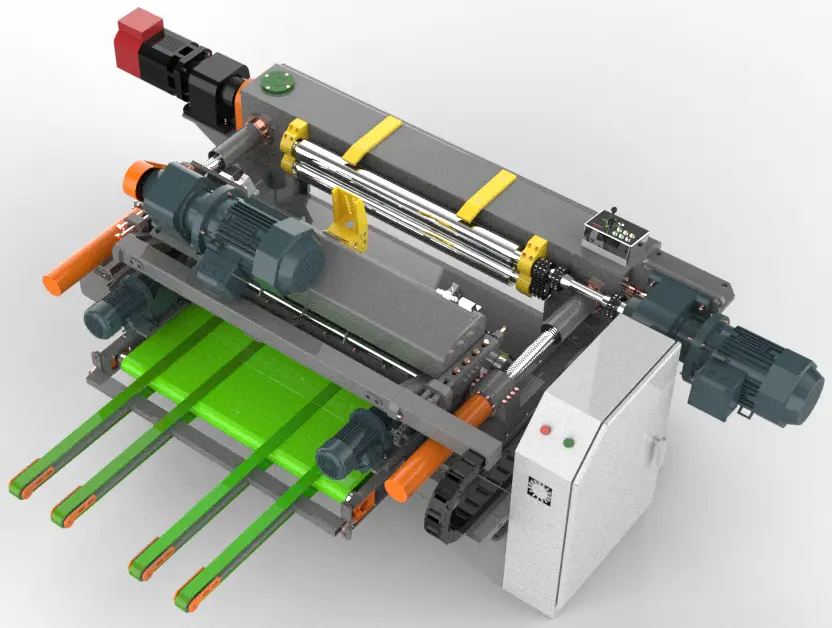

2. Automation Level:

Machines with a higher level of automation can perform tasks such as automatic log feeding, automatic veneer peeling, and automatic veneer trimming. These machines are much more expensive compared to machines with lower automation, as fully automated peeling machines require advanced sensors, complex control systems (such as PLC systems), high-precision mechanical drive systems, and automated material handling systems. These advanced technologies and components significantly increase the machine’s cost.

3. Market Supply and Demand:

When the demand for veneer peeling machines exceeds the supply in the market, prices will rise; conversely, prices may drop when the supply exceeds demand.

For investors who are sensitive to the price of a Wood Veneer Peeling Machine, buying a second-hand machine can be a viable option. Many machines that have only been used for two or three years can be purchased for 50%-70% of the original price, saving a significant amount of money. This is especially appealing to small-scale woodworking businesses or individual operators with limited budgets. In the Chinese market, second-hand plywood equipment (such as hot presses, cold presses, veneer peeling machines, dryers, etc.) is in wide demand.

If you’re looking for the right Wood Veneer Peeling Machine for your business, feel free to contact us. We offer various models of veneer peeling machines to meet different production needs and provide professional support and advice.