A veneer lathe, also known as a veneer peeling machine, is a key piece of machinery in the wood processing industry, primarily used for producing thin sheets of wood veneer. It plays an essential role in plywood manufacturing, wood panel production, and furniture-making. This article provides a detailed overview of the working principle, structure, and main applications of veneer lathes.

1. What is a Veneer Lathe?

A veneer lathe is a type of woodworking machinery used to peel continuous sheets of veneer from a log. It is one of the most efficient methods of producing veneer, maximizing wood utilization and ensuring high-speed output.

The veneer lathe is commonly used in plywood production, as the thin veneer sheets obtained through rotary cutting can be layered and bonded to form strong and durable panels.

2. Working Principle of a Veneer Lathe

2.1 Cutting Process

1. Log Preparation: The log is debarked and trimmed to the required length.

2. Fixing the Log: The log is clamped onto the veneer lathe, either using a spindle (spindle veneer lathe) or without a spindle (spindleless veneer lathe).

3. Rotary Cutting: The log is rotated at a controlled speed while a cutting knife moves forward to peel thin sheets of veneer continuously.

4. Thickness Adjustment: The pressure and cutting angle of the knife determine the veneer thickness, which is usually between 0.5mm and 3mm.

5. Veneer Output: The peeled veneer is guided through rollers and stacked for drying and further processing.

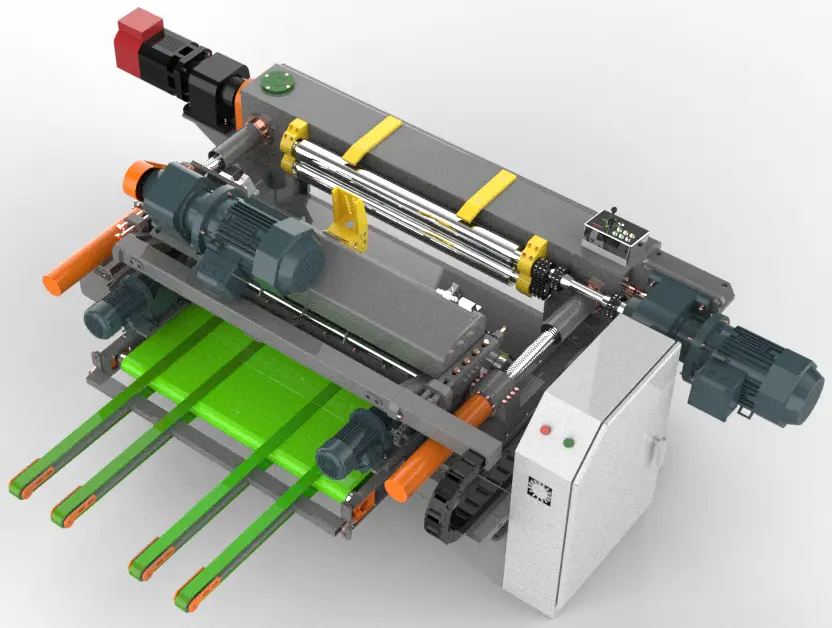

2.2 Structure of a Veneer Lathe

A veneer lathe typically consists of the following components:

- Main Frame: Supports the machine and provides stability.

- Clamping System: Holds the log in place during cutting (spindle or spindleless).

- Knife Assembly: The main cutting blade peels the veneer from the log.

- Rollers and Conveyors: Transport the veneer sheets for further processing.

- Control System: Adjusts rotation speed, cutting depth, and veneer thickness.

3. Types of Veneer Lathes

There are two main types of veneer lathes, classified based on how the log is clamped:

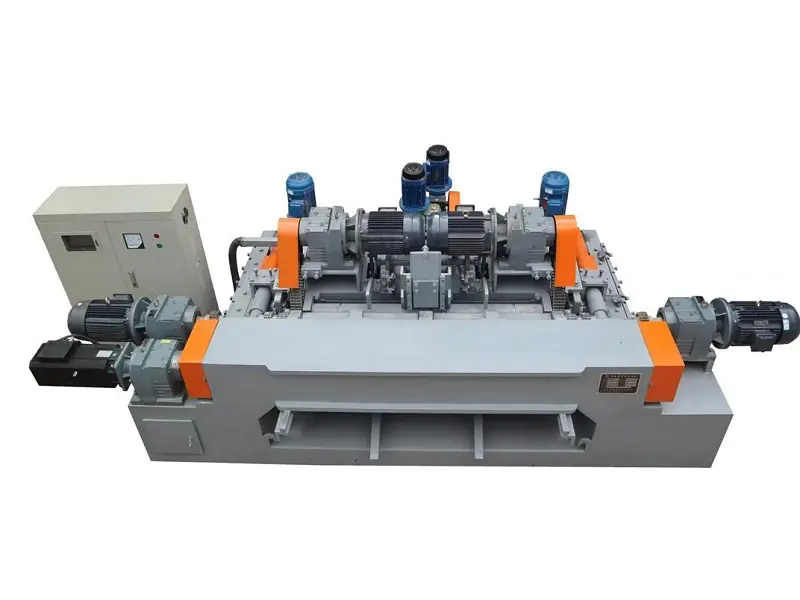

3.1 Spindle Veneer Lathe

- Uses a central spindle to hold the log while it rotates.

- Suitable for large-diameter logs and high-precision veneer cutting.

- Produces high-quality, uniform veneer sheets.

- More expensive but offers better cutting accuracy.

3.2 Spindleless Veneer Lathe

- Uses friction rollers instead of a spindle to rotate the log.

- Ideal for small-diameter logs and maximizing wood utilization.

- Can peel the log down to a very thin core, reducing wood waste.

- More cost-effective and widely used in plywood factories.

4. Applications of Veneer Lathes

Veneer lathes are widely used in various industries that require thin wood veneers. Some of the key applications include:

4.1 Plywood Manufacturing

- The most common use of veneer lathes is in the plywood industry.

- Rotary-cut veneer is glued together in multiple layers to create strong, durable plywood panels.

- Used for furniture, construction materials, and packaging panels.

4.2 Wooden Packaging & Crates

- Many shipping crates and pallets are made from veneer-based panels.

- Veneer lathes allow for cost-effective, large-scale production of packaging materials.

4.3 Furniture Manufacturing

- Veneer sheets are used as a surface layer for wooden furniture.

- Provides a smooth, uniform finish for tabletops, cabinets, and doors.

4.4 Construction and Interior Design

- Used for wall panels, flooring, and decorative surfaces.

- Offers a cost-effective alternative to solid wood for large-scale construction projects.

5. Advantages of Veneer Lathes

✅ High Efficiency: Capable of continuous veneer production at high speeds.

✅ Maximizes Wood Utilization: Especially with spindleless models, minimizing wood waste.

✅ Cost-Effective: Produces thin veneer sheets that can be used in various industries.

✅ Versatile Applications: Essential for plywood, furniture, and packaging.

6. Recommended International Veneer Lathe Brands

In the global market, several well-known veneer lathe manufacturers are leading the industry, including:

- Raute (Finland) – High-end plywood equipment with high precision, suitable for industrial-level production.

- Meinan (Japan) – Leading spindleless rotary cutting technology, ideal for high-precision requirements.

- Fezer (Brazil) – A well-known brand in the Latin American market, offering stable equipment.

- TMC Machinery (China) – High cost-performance veneer lathes, suitable for small and medium-sized plywood factories.

Conclusion

A veneer lathe is a vital machine in the woodworking and plywood industry, enabling efficient and large-scale veneer production. Whether using a spindle or spindleless veneer lathe, these machines ensure high productivity and minimal wood waste, making them an indispensable tool for plywood manufacturers, furniture makers, and construction companies.

If you are looking for high-quality veneer lathes, contact TMC Machinery for professional solutions!