What is a Veneer Peeling Machine?

A veneer peeling machine is equipment specifically designed to cut logs of a certain length and diameter into thin wood sheets (veneers). It operates by rotating the logs and using a cutting tool to slice layers from the surface of the wood, producing veneers with uniform thickness and smooth surfaces. The main technical parameters of a veneer peeling machine are the maximum length and diameter of the logs it can process. Veneer peeling machines play an important role in furniture production, plywood manufacturing, and other wood product processing industries.

Veneer peeling machines are divided into two types: spindle veneer peeling machines and spindleless veneer peeling machines(Click to Learn About Related Products). Spindle veneer peeling machines are suitable for large-diameter logs, while spindleless veneer peeling machines are suitable for logs with a diameter of less than 500 mm.

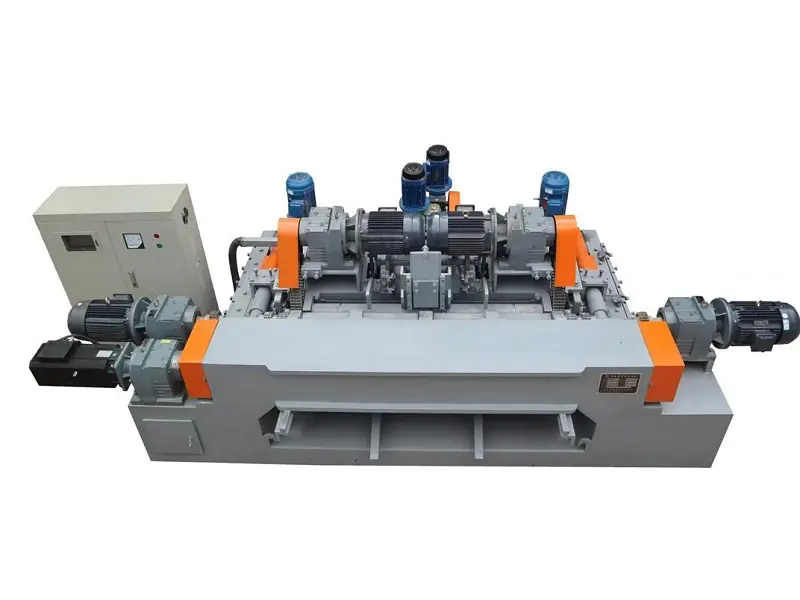

1. Working Principle of Spindle Veneer Peeling Machines

Spindle veneer peeling machines use clamps (commonly referred to as “spindles”) to firmly secure the log onto the workbench or rotating shaft of the machine, ensuring that the log does not slip or wobble during the peeling process.

After the log is secured, it begins to rotate at high speed. The rotation is driven by a motor, which ensures the rotation speed remains constant, facilitating the layer-by-layer cutting of the wood by the tool. The angle and depth of the cutting tool on spindle veneer peeling machines can be adjusted according to requirements, ensuring that the thickness of the peeled veneer remains consistent.

The spindle in spindle veneer peeling machines is primarily used to fix the wood and enable its rotation and cutting. However, the part of the wood into which the spindle is inserted cannot be peeled. Additionally, the diameter of the spindle is relatively large, leaving a significant portion of unpeeled wood, which reduces the utilization of the wood and increases production costs.

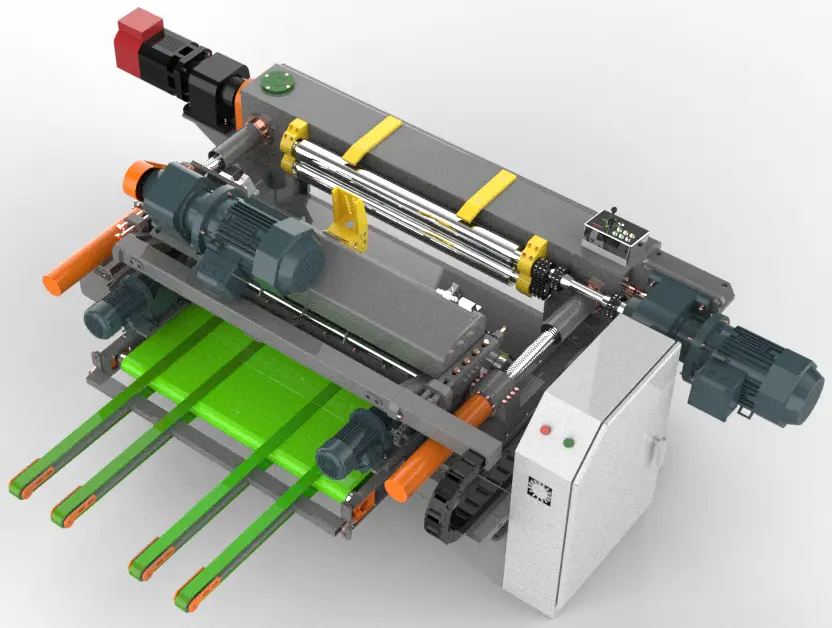

2. Working Principle of Spindleless Veneer Peeling Machines

Spindleless veneer peeling machines use a pressing friction roller that serves both as a pressing and feeding mechanism, along with two main friction rollers with textured surfaces that press and provide friction-driven support for the logs. A cutting knife positioned beneath the pressing friction roller slices into the log.

Since there is no spindle, the leftover wood core after peeling is small, with a diameter of only about 30 mm. This significantly increases the veneer yield, making spindleless veneer peeling machines widely valued.