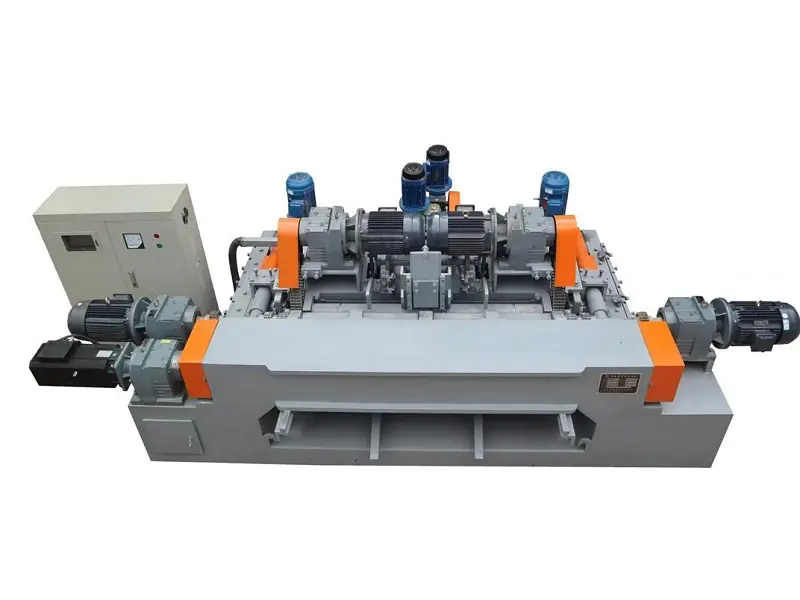

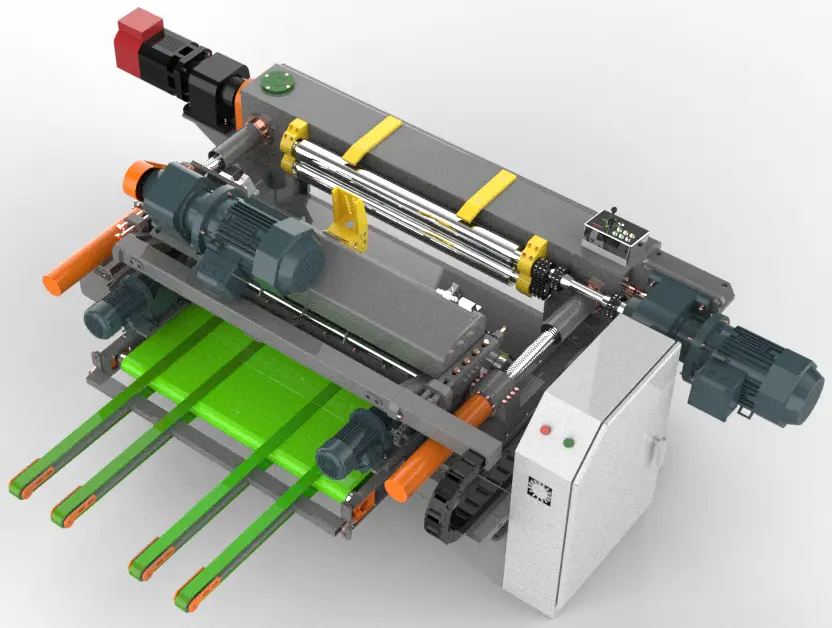

During long-term operation, various components of the rotary veneer lathe are subject to high-intensity use, mechanical friction, and environmental factors, making them prone to wear and damage. To ensure stable machine operation and improve veneer quality, this guide summarizes the common vulnerable parts of rotary veneer lathes and their maintenance techniques.

I. Vulnerable Parts of the Rotary Veneer Lathe

1. Cutting Blade

Causes of Damage: The cutting blade is the core component of the rotary veneer lathe. Long-term use causes friction, leading to dull edges, uneven veneer thickness, or rough surfaces. Additionally, incorrect blade positioning or improper blade gap settings accelerate blade wear.

Maintenance Methods:

- Regularly check the sharpness of the blade; sharpen or replace it when dull.

- Use an oil stone to refine the blade edge, ensuring smooth and sharp cutting.

- Adjust the correct blade position and blade gap to reduce unnecessary wear.

2. Bearings

Causes of Damage: Bearings in components such as the single and double roller systems and transmission mechanisms endure high-speed operation and significant pressure, making them prone to wear, excessive clearance, and reduced peeling accuracy over time.

Maintenance Methods:

- Regularly check for abnormal noise or vibration in the bearings and replace them if damaged.

- Ensure proper lubrication to prevent dry friction that shortens bearing lifespan.

3. Feeding Screw

Causes of Damage: Prolonged use may result in mechanical wear, reducing precision and affecting veneer thickness uniformity, potentially causing excessive thickness variation at the end of the veneer.

Maintenance Methods:

- Regularly check the lubrication condition of the screw to ensure smooth operation.

- If uneven feeding occurs, adjust or replace the feeding screw as needed.

4. Pressure Roller

Causes of Damage: Prolonged pressure on wood can cause wear, surface deformation, or loss of elasticity.

Maintenance Methods:

- Inspect the roller surface weekly for cracks or wear.

- Regularly clean resin, wood chips, and other debris from the roller.

- Replace damaged rollers promptly to maintain stable pressing performance.

5. Feeding Roller

Causes of Damage: Continuous contact with wood leads to wear or deformation, while damaged bearings can cause inefficient rotation.

Maintenance Methods:

- Apply lubricating oil regularly to ensure smooth bearing movement.

- Check the roller surface for clear teeth patterns; replace the roller if excessively worn.

- Avoid processing overly dry or excessively humid wood to reduce roller load.

6. Guide Rail & Slide Block

Causes of Damage: Continuous friction over time leads to wear on the guide rail surface, affecting the stability of the knife bed.

Maintenance Methods:

- Inspect the guide rail surface for smoothness; repair or replace it if severely worn.

- Adjust the gap between the guide rail and the slide block to ensure stable operation of the knife bed.

7. Press Bar & Knife Holder

Causes of Damage: Friction between the press bar and knife holder over time can cause wear, leading to unstable blade positioning and reduced peeling accuracy.

Maintenance Methods:

- Regularly check the fit between the knife holder and the press bar; adjust or repair if loose.

- Ensure accurate blade installation to minimize unnecessary vibration and misalignment.

II. Maintenance and Care Techniques for Rotary Veneer Lathes

2. Daily Inspection

Blade Inspection: Regularly check the sharpness of the blade and sharpen or replace it when necessary.

Bearing Inspection: Listen for unusual noises or vibrations in the bearings; replace worn-out bearings promptly.

Screw Inspection: Observe whether the feeding screw operates smoothly and is properly lubricated; replace if worn.

Roller Inspection: Ensure that feeding and pressure rollers are intact, clean, and free from cracks, replacing damaged parts as needed.

2. Regular Lubrication

Lubrication Points: Bearings, guide rails, gears, and feeding screws should be lubricated to minimize mechanical friction and extend equipment life.

Lubrication Frequency: Before running the machine, ensure full lubrication. After 200 hours of operation, apply lubrication twice every 8 hours.

3. Cleaning and Maintenance

Machine Cleaning: Regularly remove wood chips, dust, and other debris to prevent clogging or equipment damage.

Oil System Cleaning: Keep the lubrication system clean; replace oil if it degrades or clogs.

4. Equipment Adjustment

Blade Positioning: Adjust blade height and gap according to wood characteristics to ensure veneer quality.

Guide Rail Adjustment: Ensure the guide rail gap is properly set to prevent unstable movement or excessive friction.

Feeding and Pressing Adjustments: Ensure smooth feeding to avoid quality issues caused by worn feeding rollers or pressure rollers.

5. Regular Overhaul

Inspection Frequency: Conduct a comprehensive check every 200 hours of operation to keep the equipment in optimal condition.

Inspection Content: Examine the blade, bearings, screws, guide rails, and feeding system for damage and repair or replace parts as needed.

6. Standardized Operation

Operator Training: Ensure operators are familiar with machine performance and proper handling techniques to minimize faults.

Safety Compliance: Do not wipe, lubricate, or perform maintenance while the machine is running to prevent accidents.

III. Conclusion

The efficient operation of a rotary veneer lathe depends on the stability of its components, especially vulnerable parts such as blades, bearings, screws, feeding rollers, and pressure rollers. Through regular inspection, lubrication, cleaning, equipment adjustment, and periodic overhauls, the machine’s lifespan can be significantly extended, veneer quality can be improved, and production efficiency can be ensured.