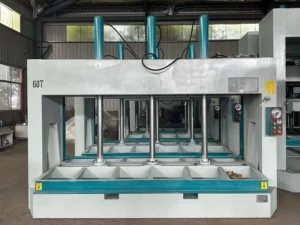

Cold Press Machine

The plywood cold press machine (pre-press) is a high-efficiency device specifically designed for plywood production. It is primarily used to pre-press multiple layers of veneer and adhesive, ensuring tight bonding and enhancing the efficiency of the hot pressing process. With a robust structure, easy operation, and uniform pressure distribution, this machine significantly reduces glue waste and product deformation. It is an ideal choice for improving production quality and efficiency in various plywood production lines.

Description

Features:

- The machine features a compact structure, stable performance, and long-lasting durability.

- The upper and lower pressing plates are precision-milled by gantry milling machines to ensure absolute flatness.

- The control panel is user-friendly and equipped with an emergency stop protection switch.

- Operates with a hydraulic system, offering fast lifting speeds, uniform pressure distribution, and high efficiency.

- Equipped with an overpressure automatic control circuit and pressure oil cut-off protection, enabling automatic lifting and oil cut-off.

Technical parameters:

| Specification | Details |

|---|---|

| Pressure | 400T |

| Voltage | 220V/380V/440V/Customize |

| Key Selling Points | Automatic |

| Cylinder | 320mm2 and 80mm2 |

| Cylinder Stroke | 1050mm |

| Pump Working Pressure | 16.5 Mpa |

| The Max Opening | 1800mm |

| Composite Frame | Assembled |

| Upper and Bottom Beam | 900mm |

| Middle Beam | 400mm |

| Work Plate Size | 2700*1370mm |

| Dimension | 3550*1370*4650MM |

| Net Weight | 14000kg |

FAQ

How should I pay for my order?

A: You’ll need to pay a 30% deposit to start production. Once the machine is finished, we’ll send you pictures or videos. After you pay the remaining balance, we’ll ship the machine.What is the delivery time?

A: Standard machines usually take 10-15 days. Customized machines may take 15-30 days depending on the specifications.How are the products packaged?

A: We typically use wooden crates or plastic film for packaging. Wooden crates are for consolidated shipping, while plastic film is used for full-container shipments.Do you offer warranty services?

A: Yes, we offer a 12-month warranty on the machine. If any issues arise during normal use, we’ll provide spare parts free of charge. Plus, you’ll receive lifetime technical support and service.Do you provide installation services?

A: Yes, we offer installation assistance. For most machines, we’ll guide you through the process via online meetings or detailed video instructions. For more complex machines that require on-site setup, our technical team can visit your factory to install and ensure everything runs smoothly. Please note, travel expenses for our technicians are your responsibility.

Related Products

Related products

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French), and العربية (Arabic). Our professional team will respond to you within one business day. Please feel free to contact us.