As a key piece of equipment in the wood processing industry, the hydraulic hot press machine for plywood has experienced rapid development and transformation in recent years due to technological advancements and changing market demands. This article will explore the industry development trends and future outlook for hydraulic hot press machines for plywood, providing valuable insights for industry professionals and investors.

I. Current Industry Development Trends

1.Smart and Automated Technology

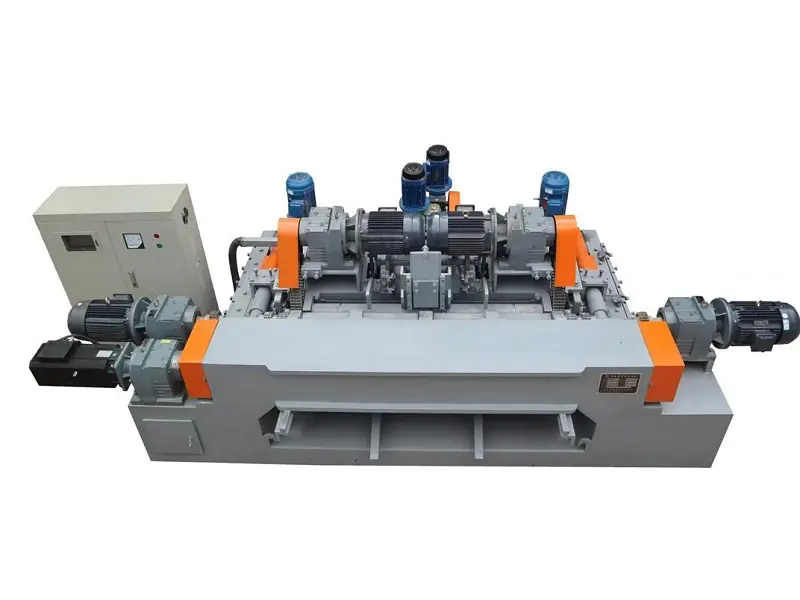

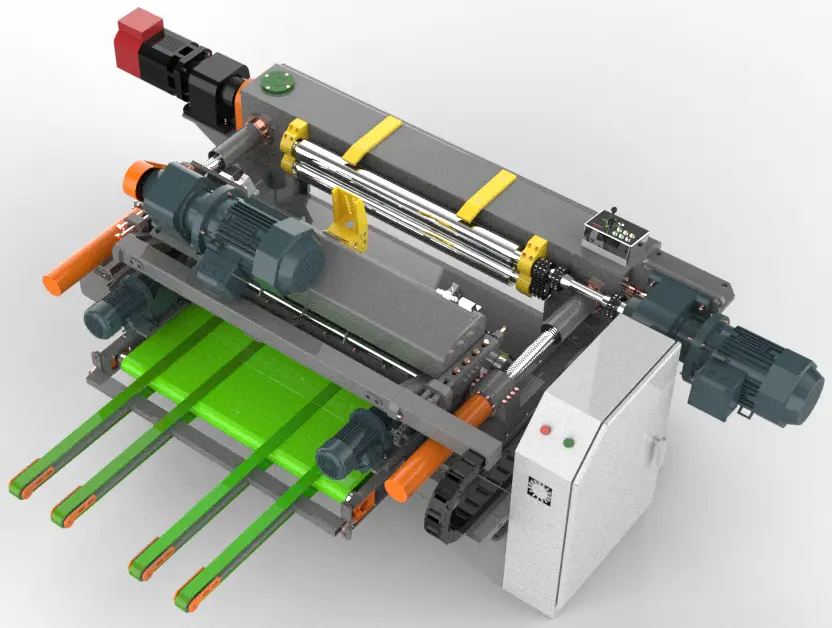

With the advancement of Industry 4.0, hydraulic hot press machines for plywood are gradually evolving toward smarter and more automated systems. Modern hot presses, integrated with sensors and artificial intelligence technologies, can automatically optimize production parameters such as pressure, temperature, and time to accommodate different types of wood and adhesives. This intelligent production mode not only improves production efficiency but also enhances product quality and consistency.

2.Environmental Protection and Energy Efficiency

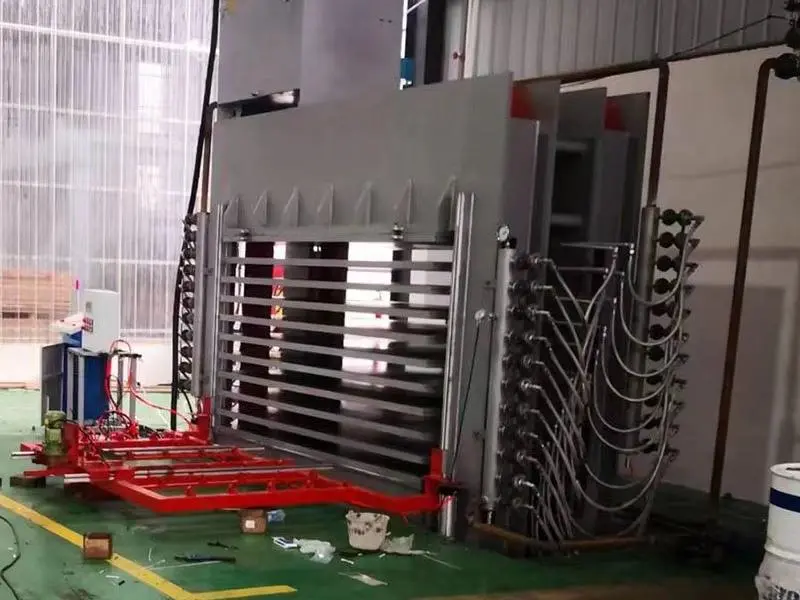

With growing global emphasis on environmental protection and sustainable development, energy efficiency and environmental performance have become focal points in the industry. Modern hydraulic hot press machines for plywood feature more efficient heating systems and closed-loop systems, reducing energy consumption and emissions. Additionally, hot press technologies using renewable and recyclable materials are continuously developing to meet the goals of a circular economy and zero-waste production.

3.Modular and Customizable Design

To meet the demands for small-batch, multi-variety custom production, the design of hydraulic hot press machines for plywood is becoming more modular and flexible. This design not only reduces the initial investment costs but also enhances the versatility and scalability of the equipment, enabling it to better serve the diverse needs of customers.

4.Market Demand Growth

With the continued growth of the global construction and furniture manufacturing industries, particularly in emerging markets in Asia, Africa, and Latin America, the demand for plywood is expected to keep rising. As one of the core devices in plywood production, hydraulic hot press machines for plywood are naturally in greater demand alongside this growth. In 2023, the global plywood hot press machine market reached a certain scale in sales, and it is expected to experience significant growth by 2030, with a stable compound annual growth rate (CAGR).

II. Future Outlook

1.Technological Innovation Driving Industry Upgrades

In the future, the hydraulic hot press machine for plywood industry will continue to benefit from technological innovation. On one hand, smart technology will become more widespread, enabling remote monitoring and fault diagnosis of equipment through the Internet of Things (IoT). On the other hand, the application of new materials and energy-saving technologies will further enhance the performance and energy efficiency of the equipment.

2.Green and Sustainable Development

In line with the global trend toward green development, the hydraulic hot press machine for plywood industry will place greater emphasis on environmental protection and sustainability. In the future, equipment manufacturers will focus on developing low-energy, low-emission hot presses and promoting the use of renewable energy in production. Additionally, the lifespan and recyclability of equipment will become important design considerations.

3.Expansion into Emerging Markets and New Application Areas

With the rise of emerging markets and the upgrading of consumption, the application areas for hydraulic hot press machines for plywood will continue to expand. Beyond traditional wood processing industries, these machines will play a more significant role in construction, furniture, packaging, and other sectors. In particular, in developing countries, as infrastructure development and urbanization accelerate, the demand for plywood will continue to rise.

4.Increased Industry Concentration

As market competition intensifies, the concentration of the hydraulic hot press machine for plywood industry will further increase. In the future, mergers and acquisitions (M&A) and industry consolidation will accelerate. Large enterprises will capture a greater market share through technological innovation and economies of scale. Meanwhile, small and medium-sized enterprises will focus on specialized and differentiated competition to find new market opportunities.

Conclusion

The hydraulic hot press machine for plywood industry is experiencing rapid technological progress and market transformation. The main trends driving current industry development include smart technology, environmental friendliness, modularity, and customization. Moving forward, with the support of technological innovations and growing market demand, the industry is set to face a broader development space. However, investors and industry players must also be mindful of the risks posed by technological updates, market competition, and policy changes, and plan ahead for sustainable development.(Read more related articles on hot press machines.)