In the wood processing industry, rotary veneer cutting machines,also known as veneer peeling machines, are essential equipment for producing high-quality veneers. Selecting the right rotary veneer cutting machine can not only improve production efficiency but also ensure the quality of the veneers and the economic benefits of the company. This article provides a comprehensive guide to help you choose the most suitable rotary veneer cutting machine for your business.

Define Production Requirements

Before choosing a rotary veneer cutting machine, businesses must first define their production requirements. This includes the types of wood to be processed, veneer thickness and width requirements, and expected production volume. Different types of wood have different characteristics, such as hardness and grain, which require different tool and machine performance specifications. The equipment’s structural design also varies. For example, when processing hardwood, a cutting machine needs more power and more durable blades, while processing softwood may require higher precision. The production volume will also determine the required production efficiency. Companies with large production volumes should opt for high-speed, highly automated rotary veneer cutting machines.

Currently, a type of rotary veneer cutting machine called “pressure-tooth rotary cutting machine” is popular in the Chinese market. It is particularly suitable for processing hardwood or veneers thicker than 3mm. The working principle of the pressure-tooth rotary cutting machine is similar to that of the traditional shaftless rotary cutting machine, but the pressure-tooth machine adds a special “pressure-tooth” structure to the single roll. These pressure-tooth structures help the blade better contact and press the wood, ensuring smooth and neat veneer surfaces during cutting. This type of machine is significantly more expensive than traditional equipment.

Understand the Types of Rotary Veneer Cutting Machines

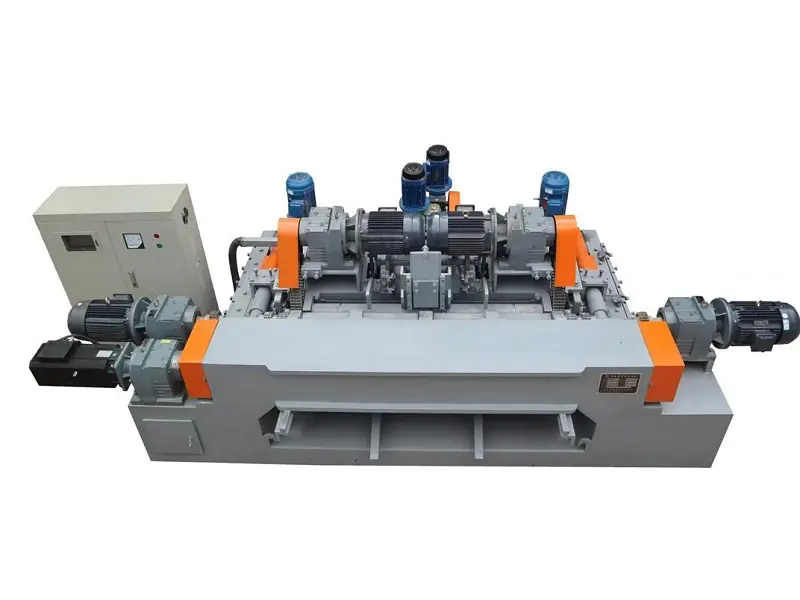

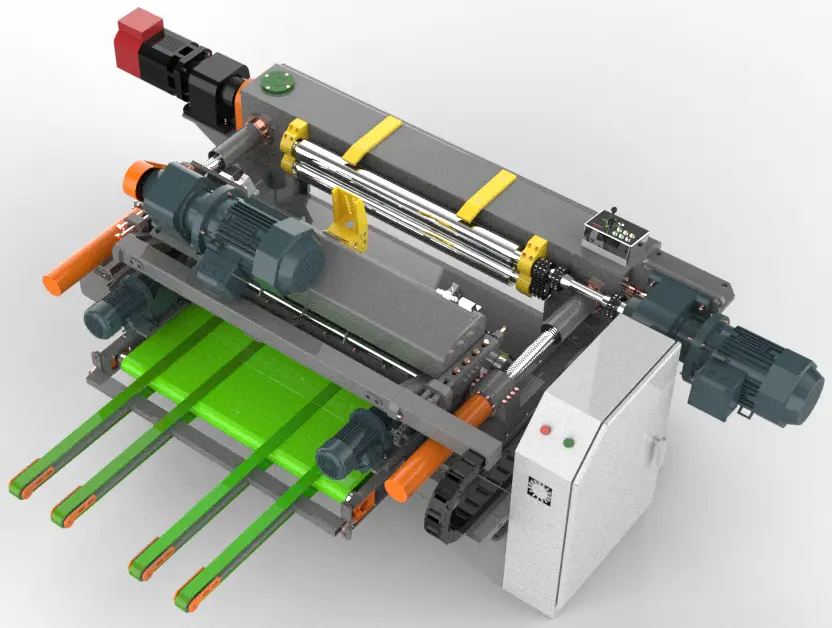

Rotary veneer cutting machines are mainly divided into two categories: shafted rotary cutting machines and shaftless rotary cutting machines.

1.Shafted Rotary Cutting Machine

Shafted rotary cutting machines fix the logs via a spindle, making them suitable for large-scale production. They can handle logs with larger diameters. The advantages include stable structure, suitable for producing thicker veneers, but they are more complex to operate and have higher maintenance costs.

2.Shaftless Rotary Cutting Machine

Shaftless rotary cutting machines use friction rollers to drive the logs, without the need for a spindle. They are suitable for small and medium-sized enterprises. The advantages of these machines include simple operation, easy maintenance, and the ability to produce high-quality thin veneers.

Focus on Technical Parameters

When choosing a rotary veneer cutting machine, it is important to focus on the following technical parameters:

1.Processing Diameter and Length

Select the appropriate cutting machine based on the size of the logs. For example, large rotary cutting machines can handle logs with a diameter of up to 1600mm and a length of 2700mm, while smaller machines are suitable for logs with diameters under 500mm and lengths under 1400mm.

2.Veneer Thickness

Veneer thickness is an important factor in choosing a rotary cutting machine. Different machines have different thickness adjustment ranges. For instance, the TMC Machinery shaftless rotary cutting machine can adjust the veneer thickness from 0.2mm to 4.0mm.

3.Cutting Speed

High-speed cutting can improve production efficiency, but it may affect the veneer quality. If you want to balance both quality and efficiency, a CNC rotary cutting machine is a good option. CNC rotary cutting machines are usually equipped with high-precision servo motors and automatic lubrication systems, which enable fast and efficient cutting.

On-Site Inspection and Trial Runs

Before purchasing a rotary veneer cutting machine, it is recommended to conduct an on-site inspection of the equipment’s operation and perform a trial run. This will give you a direct understanding of the machine’s performance and ease of operation.

Conclusion

There are various brands and models of rotary veneer cutting machines available on the market. Only through thorough and detailed analysis and comparison can you select the most suitable rotary veneer cutting machine for your business. This will provide strong support for your wood processing operations and ensure efficient and stable production.