A plywood sanding machine(also known as Plywood Sander) is a woodworking tool specifically designed for sanding, polishing, and leveling the surface of plywood. Its primary functions include:

- Removing burrs and surface irregularities to improve the quality of plywood and meet further processing requirements.

- Sanding down excessive thickness to ensure uniformity across the entire sheet.

So, how should plywood manufacturers select the right sanding machine? Here are some key factors and recommendations.

Understand Plywood Characteristics and Processing Needs

1.Thickness Considerations

For thicker plywood (e.g., above 18mm), the sanding machine must have strong cutting power. This requires a high-power motor to effectively remove surface irregularities and burrs. For thin plywood (e.g., 3-6mm), higher precision and finer sanding adjustments are needed to prevent sanding through the material.

2.Material Type

Hardwood plywood has higher hardness and requires a sanding machine equipped with high-quality, high-speed sanding belts to ensure efficient cutting. Softwood plywood requires less cutting power but still needs to ensure a smooth and even surface after sanding.

3.Production Scale

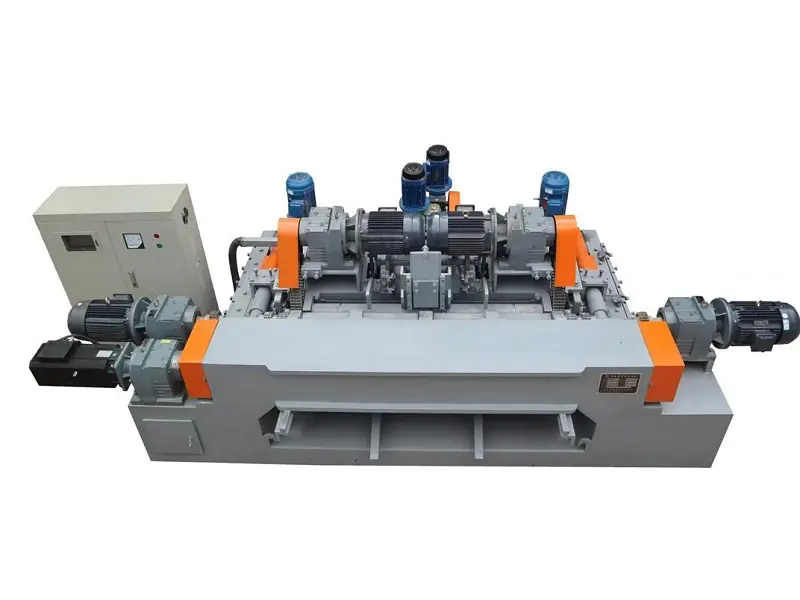

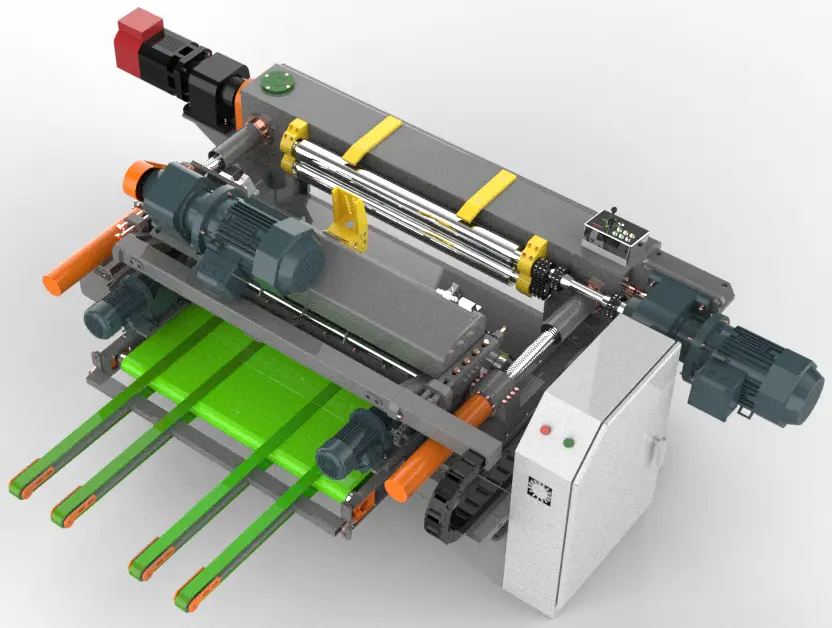

Large plywood manufacturers focusing on high output and efficiency should choose wide belt sanding machines with automated feeding and continuous sanding capabilities, significantly improving productivity. Small workshops can opt for flexible and budget-friendly disc or belt sanding machines.

4.Sanding Precision

For high-end furniture or decorative plywood, which requires an extremely smooth surface, a multi-head high-precision sanding machine is essential. For example, a four-head sanding machine can complete coarse, medium, fine, and precision sanding in one pass. For standard construction plywood, where surface smoothness is less critical, a simple and cost-effective sanding machine is sufficient.

Pay Attention to the Performance Parameters of the Plywood Sanding Machine

1.Sanding Belt Quality

The sanding belt is one of the core components of a sanding machine, directly affecting sanding efficiency and durability. A high-quality belt should be wear-resistant, provide strong cutting power, and have uniform grit distribution. It is recommended to choose well-known brands such as 3M or Norton.

2.Sanding Power

The power of a sanding machine determines its cutting ability and efficiency, typically ranging from 3 to 15kW. For large-area, thick plywood sanding, a higher-power machine (11-15kW) is recommended to ensure efficient removal of excess material. For small-area or thin plywood sanding, machines with 3-7kW power are usually sufficient.

3.Feeding Speed

The feeding speed affects both productivity and sanding quality. It should be adjusted based on the plywood material, thickness, and sanding process requirements. Typically, sanding machines offer a speed range of 5-30m/min:

- For harder and thicker plywood, reducing the feeding speed ensures better sanding quality.

- For softer and thinner plywood, increasing the feeding speed improves efficiency.

Choosing the Right Brand and Supplier

When purchasing a sanding machine, consider the following factors:

- Manufacturer Reputation – Choose a brand with years of experience and a solid market reputation to ensure equipment stability.

- Customer Case Studies – Ask the supplier if they have successful applications in plywood factories to evaluate the machine’s reliability.

- After-Sales Service – Quality after-sales support, including installation, debugging, technical training, and spare parts supply, can reduce downtime and enhance production efficiency.

Conclusion: How to Choose the Right Plywood Sanding Machine?

| Requirement | Recommended Sanding Machine Type |

|---|---|

| Standard construction plywood | Cost-effective sanding machine |

| High-end furniture, decorative plywood | Multi-head, high-precision sanding machine |

| Large-scale production | Wide belt automatic sanding machine |

| Small workshops or limited budget | Disc sanding machine or belt sanding machine |

Selecting the right plywood sanding machine requires a comprehensive evaluation of plywood characteristics, processing needs, machine performance, and supplier reliability. A well-considered choice ensures the best machine for your production needs.

If you are looking for double-sided or fully automatic sanding machines, feel free to contact us for professional selection advice!