In the woodworking industry, a glue spreader machine is a common piece of equipment used in furniture manufacturing, panel production, and wood door and window processing. The introduction of glue spreader machines has significantly improved the efficiency of glue application, ensuring evenness and stability, which directly impacts the quality and lifespan of wooden products. Therefore, it is essential to explore the working principles of a glue spreader machine and its specific applications.(Read Related Article: Plywood Glue Spreader Machine Working Principle)

What is a Glue Spreader Machine?

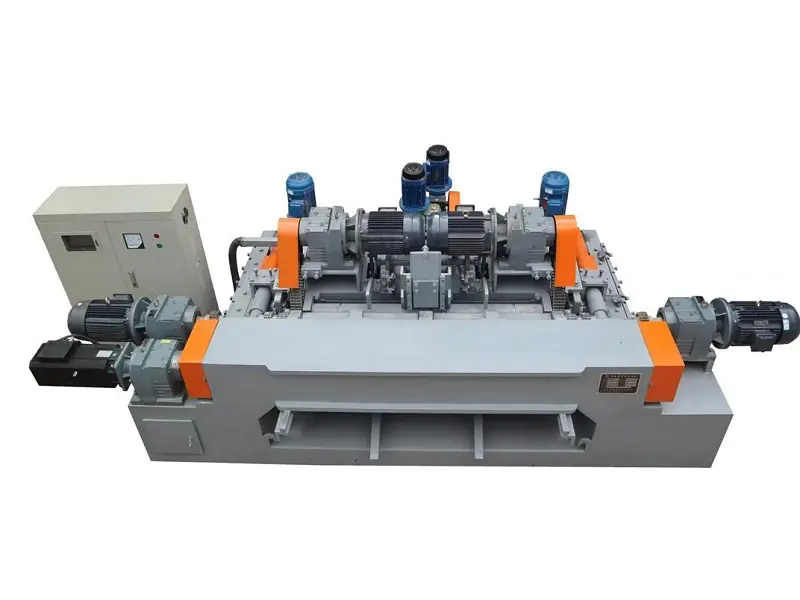

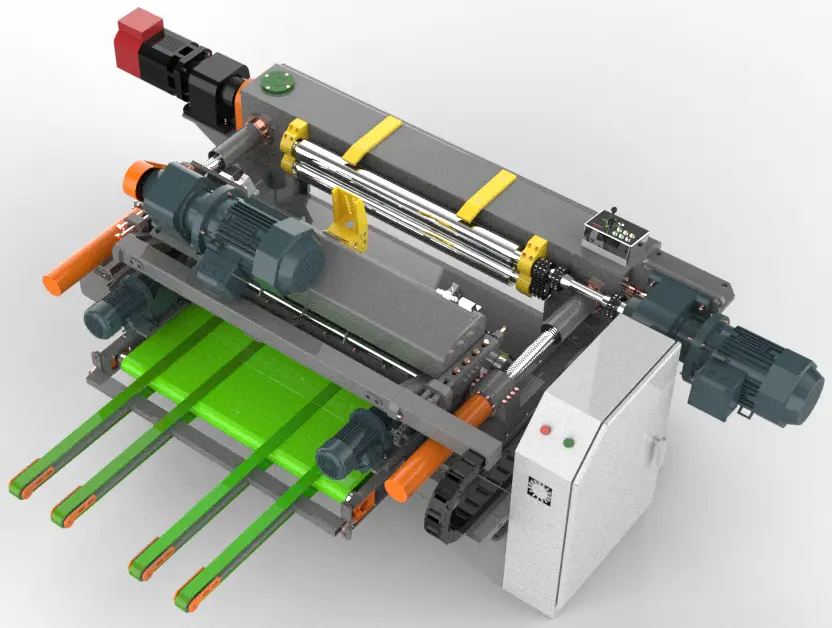

A glue spreader machine is an automated device specifically designed to evenly apply glue or adhesive to the surface of wood or wood products for bonding, sealing, decoration, and other purposes. Depending on the method of application, glue spreader machines can be classified into the following categories:

- Roller Coater: Applies glue evenly to the surface of wood via glue rollers. It is suitable for gluing flat panels.

- Spraying Machine: Uses a spray gun to atomize and spray glue onto the surface of the wood. It is ideal for irregular workpieces or complex surfaces.

- Scraper Coater: Applies glue to the surface using a scraper. It is suitable for applications where a specific layer thickness of glue is required.

- Brush Coater: Uses rotating brushes to apply glue. It is suitable for fine or irregularly shaped materials.

How Does a Glue Spreader Machine Work?

The working principle of a glue spreader machine is relatively simple, but the design and functionality can vary depending on the machine type and the materials used. The main components include the following systems:

- Glue Supply System: Glue is transported from a storage tank to the glue head via pipelines, typically powered by a glue pump or pressure device.

- Coating System: The glue head (such as a glue roller or nozzle) evenly applies glue to the wood surface. The glue roller transfers glue from the glue tank and applies it evenly, while the nozzle sprays glue onto the wood surface under high pressure.

- Control System: Operators can adjust the working speed, glue amount, and application method through a computer or other control devices, ensuring uniformity and consistency. Some advanced glue spreader machines also have sensors that monitor glue flow and pressure in real-time. If any abnormalities occur, the system alerts the operator and makes automatic adjustments to ensure smooth operation.

- Transmission Device: Provides power to drive the glue head and glue supply system, usually powered by electricity or air.

Benefits of Using a Glue Spreader Machine

1.Accuracy and Consistency

A glue spreader machine ensures uniform application of glue, reducing the likelihood of uneven bonding. This consistency is crucial in industries like plywood production and furniture manufacturing, ensuring optimal bonding in every layer.

2.Increased Production Speed

The automation of the glue application process significantly improves production speed, enabling manufacturers to meet large-scale production demands without compromising quality. This boosts production efficiency and reduces downtime.

3.Reduced Glue Waste

A glue spreader machine helps minimize glue usage by applying the exact amount required. This not only results in cost savings but also reduces glue waste, lowering environmental impact.

4.Enhanced Bonding Strength

Even application of glue enhances the bonding strength between materials, ensuring the durability of the final product. This is particularly important in plywood production, where the adhesive strength directly affects the quality of the finished product.

5.Improved Worker Safety

Manual glue application is labor-intensive and exposes workers to harmful gases or chemicals. Using a glue spreader machine reduces manual labor, improves worker safety, and avoids contact with hazardous substances.

Specific Applications

1.Furniture Manufacturing

In furniture production, a glue spreader machine is used to bond furniture components, such as joining panels, veneering, and edge banding in panel furniture. The even glue application improves the furniture’s strength and aesthetic appeal.

2.Flooring Production

In wood flooring manufacturing, a glue spreader machine is used for joint bonding and edge treatment, ensuring the flatness and sealing of the floorboards.

3.Wood Door and Window Processing

A glue spreader machine is used to bond and seal door and window frames, improving their stability and durability. It can also be used for adhering decorative materials.

4.Plywood Production

A glue spreader machine is used for single-side or double-side gluing of plywood, ensuring even glue distribution and enhancing the bonding strength of the boards.

Conclusion

In summary, a glue spreader machine, with its high efficiency, accuracy, and stability, has become indispensable in the woodworking industry. It not only improves production efficiency but also enhances the quality and appearance of products, bringing significant economic benefits to woodworking enterprises. As a leading supplier of plywood equipment, TMC Machinery offers high-quality, customizable glue spreader machines. If you’re looking for glue spreader machines, please feel free to contact us.(Related products:8 Feet Glue Spreader Machine)