In the wood processing industry, veneer peeling lathes are essential for enhancing production efficiency and product quality. As the demand for high-quality plywood continues to grow, selecting a high-performance veneer peeling lathe has become key for many wood processing companies to improve their competitiveness. This article will explore the working principle of veneer peeling lathes, key parameters, and their impact on veneer quality, helping you make more informed decisions when selecting equipment and managing production.

What is a Veneer Peeling Lathe?

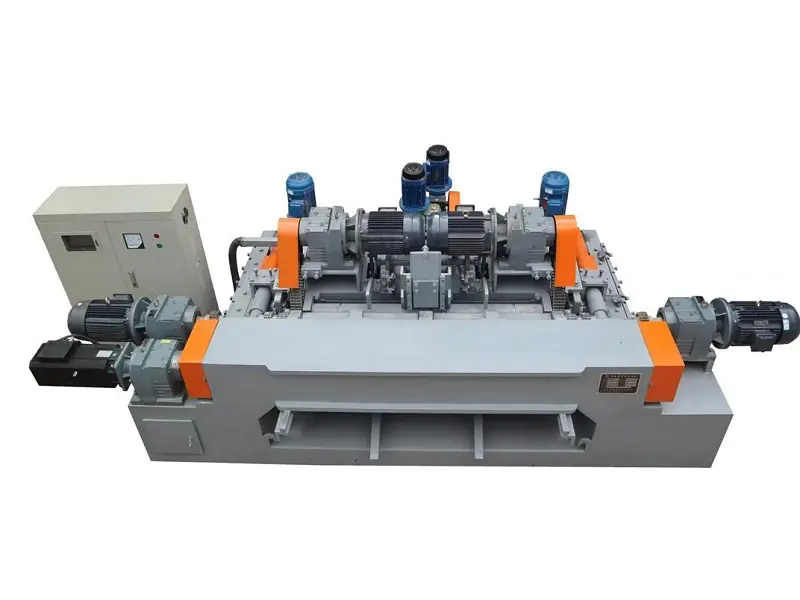

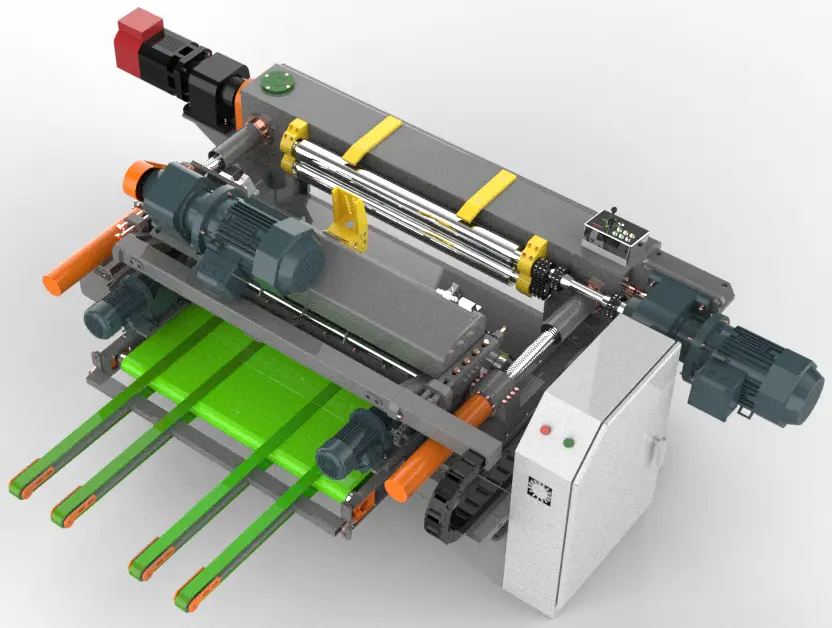

A veneer peeling lathe is specialized wood processing equipment designed to peel logs into thin veneers. By rotating the logs and using cutting tools, a veneer peeling lathe efficiently converts logs into thin veneers used for plywood, blockboard, or other wood products.

Veneer peeling lathes are generally divided into two types: spindle-type peeling lathes and spindle-less peeling lathes.

- Spindle-type peeling lathes are suitable for processing logs with larger diameters.

- Spindle-less peeling lathes are better suited for smaller diameter logs or wood cores.

Key Parameter Analysis

1. Peeling Speed

Measured in meters per minute (m/min), peeling speed determines the machine’s production efficiency.

- High-performance veneer peeling lathes can achieve speeds of 30–60 m/min or even higher.

- Faster peeling speeds increase production efficiency but may compromise veneer surface quality.

- Adjusting the speed properly helps balance efficiency and quality.

2. Peeling Precision

Measured in millimeters (mm), peeling precision affects the uniformity of veneer thickness.

- High-precision machines can control the error within ±0.05 mm.

3. Cutting Thickness

Measured in millimeters (mm). Common veneer thickness ranges from 0.5 mm to 4.0 mm.

- The sharpness of the blade and the pressure of the pressure roller directly affect thickness accuracy.

4. Processing Diameter Range

The processing diameter range determines the size of logs the machine can handle.

- Some high-end CNC peeling lathes can process logs with diameters from 140 mm to 600 mm or even larger.

5. Core Diameter

The minimum core diameter determines wood utilization efficiency.

- Spindle-less peeling lathes can reduce the core diameter to 30 mm or smaller, minimizing wood waste.

How Veneer Peeling Lathes Affect Veneer Quality

1. Thickness Uniformity

High-precision CNC systems and advanced servo motor drive technology ensure uniform veneer thickness.

- Uniform thickness is critical for plywood production since uneven thickness can cause warping or insufficient strength.

2. Surface Quality

The quality of the cutting tools and feed rate directly affect the veneer surface quality.

- High-quality cutting tools and precise feed control reduce knife marks and tearing, improving veneer surface smoothness.

3. Grain Integrity

High-quality veneer peeling lathes can maintain consistent wood grain direction while reducing knots and cracks.

- Complete wood grain not only enhances plywood strength but also improves the product’s visual appeal.

Conclusion

As a core piece of equipment in the wood processing industry, the performance of a veneer peeling lathe directly impacts production efficiency and product quality. Choosing an efficient and precise peeling lathe not only enhances a company’s competitiveness but also reduces production costs and supports sustainable development.

TMC Machinery has nearly 20 years of experience in manufacturing plywood equipment. Our veneer peeling lathes use advanced CNC systems and high-quality alloy blades, capable of meeting the production needs of various customers and helping you maintain a leading position in a highly competitive market.