The plywood glue spreader machine is one of the main equipment used in plywood production. It is designed to evenly apply a pre-mixed adhesive to the surface of veneers. The machine consists of a frame, glue rollers, glue tank, deceleration mechanism, adjustment devices, and other components.

According to the number of glue rollers, plywood glue spreader machines can be classified into double-roller, three-roller, and four-roller types. Due to the inferior performance of double-roller glue spreaders—difficulty in controlling glue quantity, potential damage to veneers, and low production efficiency—four-roller machines are more commonly used. This article mainly introduces the working principle of the four-roller glue spreader machine.

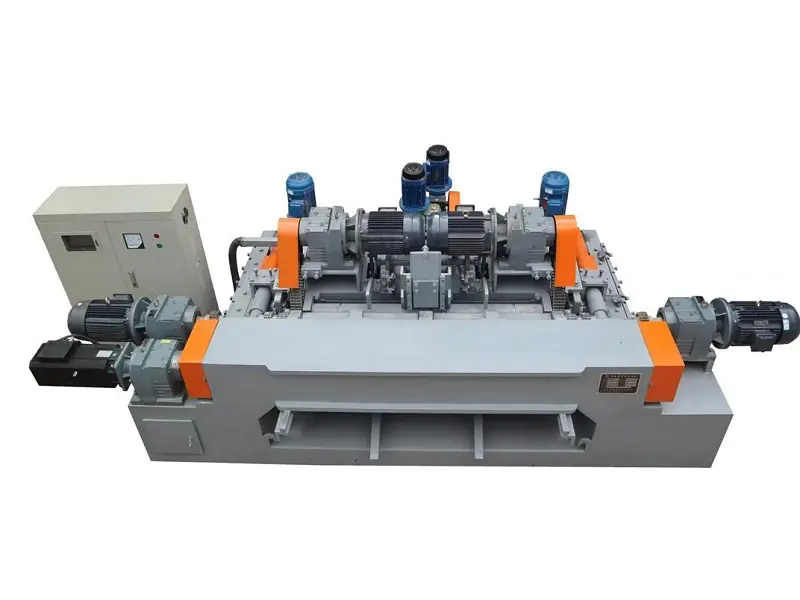

Structure of the Four-Roller Plywood Glue Spreader Machine

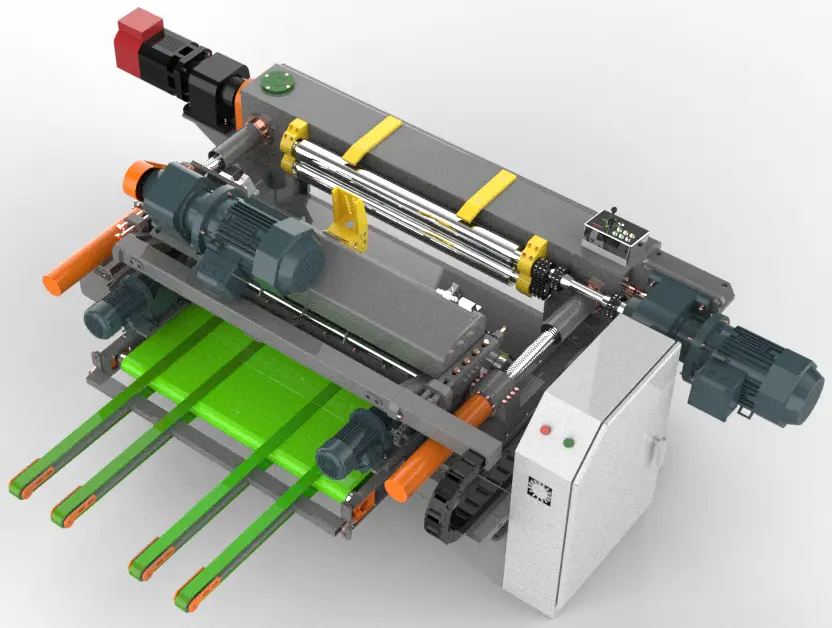

The four-roller glue spreader machine consists mainly of upper and lower glue rollers, upper and lower glue scraper rollers, glue tank, transmission device, lifting and adjustment devices, and other auxiliary components.

Glue Rollers and Scraper Rollers:

- The upper and lower glue rollers are responsible for evenly applying glue to the top and bottom surfaces of the veneer. Their surfaces are typically covered with hard rubber and feature grooves to control the amount of glue applied.

- The upper and lower glue scraper rollers control the amount of glue by moving at a speed 15%-20% slower than the glue rollers. Their role is to scrape off excess glue, ensuring an even glue layer thickness.

Glue Tank: The glue tank stores the adhesive. The lower glue roller is partially immersed in the tank and picks up the glue as it rotates, transferring it to the glue rollers.

Transmission Device: The transmission system, powered by a dual-speed motor, reducer, and chain drive, ensures the glue rollers and scraper rollers rotate smoothly, maintaining efficient operation.

Lifting and Adjustment Devices: The lifting device of the upper glue roller is used to adjust the gap between the upper and lower glue rollers, accommodating different veneer thicknesses. The scraper roller adjustment device is used to control the gap between the glue rollers and scraper rollers, thereby controlling the glue application.

Working Principle of the Four-Roller Plywood Glue Spreader Machine

Glue Supply: The adhesive is picked up by the lower glue roller from the glue tank. Through the rotation of the glue rollers, the glue is transferred to the surface of the veneer. The glue for the upper roller is supplied by a glue pump, which delivers it from the supply tank to a spray pipe that evenly sprays glue onto the surface of the glue rollers.

Glue Application: As the veneer passes between the upper and lower glue rollers, the glue is evenly applied to the top and bottom surfaces of the veneer. The glue scraper rollers, moving in the opposite direction of the glue rollers, scrape off excess glue, ensuring uniform application.

Glue Amount Control: The glue application is primarily controlled by adjusting the gap between the glue rollers and scraper rollers. The scraper rollers, moving at a slower speed than the glue rollers, perform the scraping action, further ensuring an even glue layer.

Auxiliary Functions: The cleaning tank collects excess glue that falls during the application process, preventing waste and pollution. Safety features such as an overrunning clutch and emergency stop switch ensure the safe operation of the equipment.

Technical Advantages of the Four-Roller Plywood Glue Spreader Machine

1.Efficient Glue Application: The four-roller glue spreader applies glue to both sides of the veneer simultaneously, improving production efficiency.

2.Precise Control: The gap adjustment between the glue rollers and scraper rollers allows for precise control over the glue application, ensuring high-quality adhesion.

3.Energy Saving and Environmentally Friendly: The glue recycling system minimizes waste, reducing production costs and enhancing environmental sustainability.

Conclusion

The four-roller plywood glue spreader machine is widely used in wood processing, furniture manufacturing, and other industries due to its efficient and precise glue application capabilities. It plays a key role in enhancing production efficiency and product quality.