| Model | BY214 |

| Nominal Total Pressure | 1600 KN |

| Number and Size of Hot Plate | 4 ~ 2500 × 1300 × 42 mm |

| Unit Surface Pressure | 4.9 KGF/cm² |

| Diameter of Cylinder | 100 mm |

| Closing Velocity | 40 mm/s |

| Clamp Opening Mode | Electric |

| Working Layer | 3 |

| Hot Plate Spacing | 100 mm |

| Rated Oil Pressure | 25 MPa |

| Cylinder Stroke | 300 mm |

| Installed Power | 41.5 KW |

| Max Operating Temperature | 200℃ |

| Total Weight | 7400 kg |

Multi Layer Woodworking Hydraulic Hot Press Machine

Multi layer woodworking hydraulic hot press machine can be used for wood doors, fireproof doors, and wood veneer lamination. It is suitable for secondary lamination of various board cores such as engineered boards, particle boards, foam boards, and MDF. It can laminate engineered wood veneers, metal veneers, and PVC multilayer boards.

Description

Features:

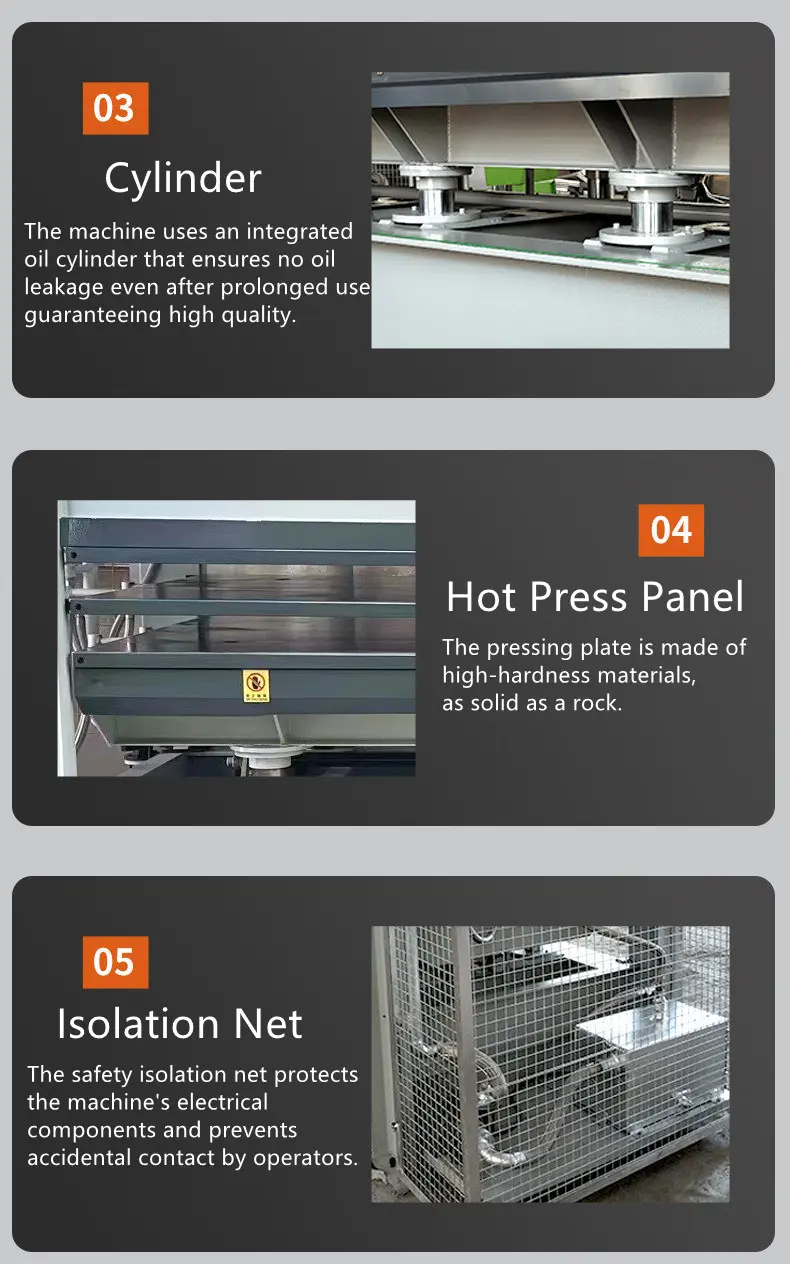

- The main frame is made of channel steel, with both sides precisely machined using CNC boring and milling.

- Solid steel heat-conducting plates are used, combined with deep hole drilling technology.

- Circulating heat transfer oil with electric heating is adopted, with an optional steam heating configuration.

- Working dimensions and pressure can be customized according to customer requirements.

Technical Parameters:

FAQ

How should I pay for my order?

A: You’ll need to pay a 30% deposit to start production. Once the machine is finished, we’ll send you pictures or videos. After you pay the remaining balance, we’ll ship the machine.What is the delivery time?

A: Standard machines usually take 10-15 days. Customized machines may take 15-30 days depending on the specifications.How are the products packaged?

A: We typically use wooden crates or plastic film for packaging. Wooden crates are for consolidated shipping, while plastic film is used for full-container shipments.Do you offer warranty services?

A: Yes, we offer a 12-month warranty on the machine. If any issues arise during normal use, we’ll provide spare parts free of charge. Plus, you’ll receive lifetime technical support and service.Do you provide installation services?

A: Yes, we offer installation assistance. For most machines, we’ll guide you through the process via online meetings or detailed video instructions. For more complex machines that require on-site setup, our technical team can visit your factory to install and ensure everything runs smoothly. Please note, travel expenses for our technicians are your responsibility.

Related Products

Related products

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French), and العربية (Arabic). Our professional team will respond to you within one business day. Please feel free to contact us.